Gases for Life

PRACTICAL FOCUS

Reliable refrigeration for food deliveries

By Editorial Team

People are ordering food on the Internet, with fresh deliveries of convenience products being made every few hours. However, diesel vehicles are increasingly being banned from city centres. Low-emission transport refrigeration therefore needs cryogenic gases.

Gases for Life

PRACTICAL FOCUS

Reliable refrigeration for food deliveries

By Editorial Team

People are ordering food on the Internet, with fresh deliveries of convenience products being made every few hours. However, diesel vehicles are increasingly being banned from city centres. Low-emission transport refrigeration therefore needs cryogenic gases.

More and more online providers are delivering packaged meals directly to the consumer. The product range in the refrigerated sections of supermarkets, petrol station shops and station kiosks is also changing, with an ever-growing variety of convenience products such as wraps, salads and portioned meals. The use-by date is being replaced by the use-by hour.

Diesels and noisy vehicles not welcome!

Food logistics has to respond. It is increasingly characterised by smaller units combined with greater speed and flexibility. But no matter what the transport side of things looks like, the cold chain must never be broken! Meanwhile, cities such as Paris, Madrid and Barcelona are restricting access for (refrigerated) diesel vehicles. Other places have banned noisy diesel-powered cooling units from residential areas. However, it is possible to harness the large reservoir of cooling offered by liquid gases without generating any noise or exhaust gases. Moreover, their cooling capacity can be regulated very precisely. Messer has developed a number of efficient and low-emission transport refrigeration systems of varying sizes.

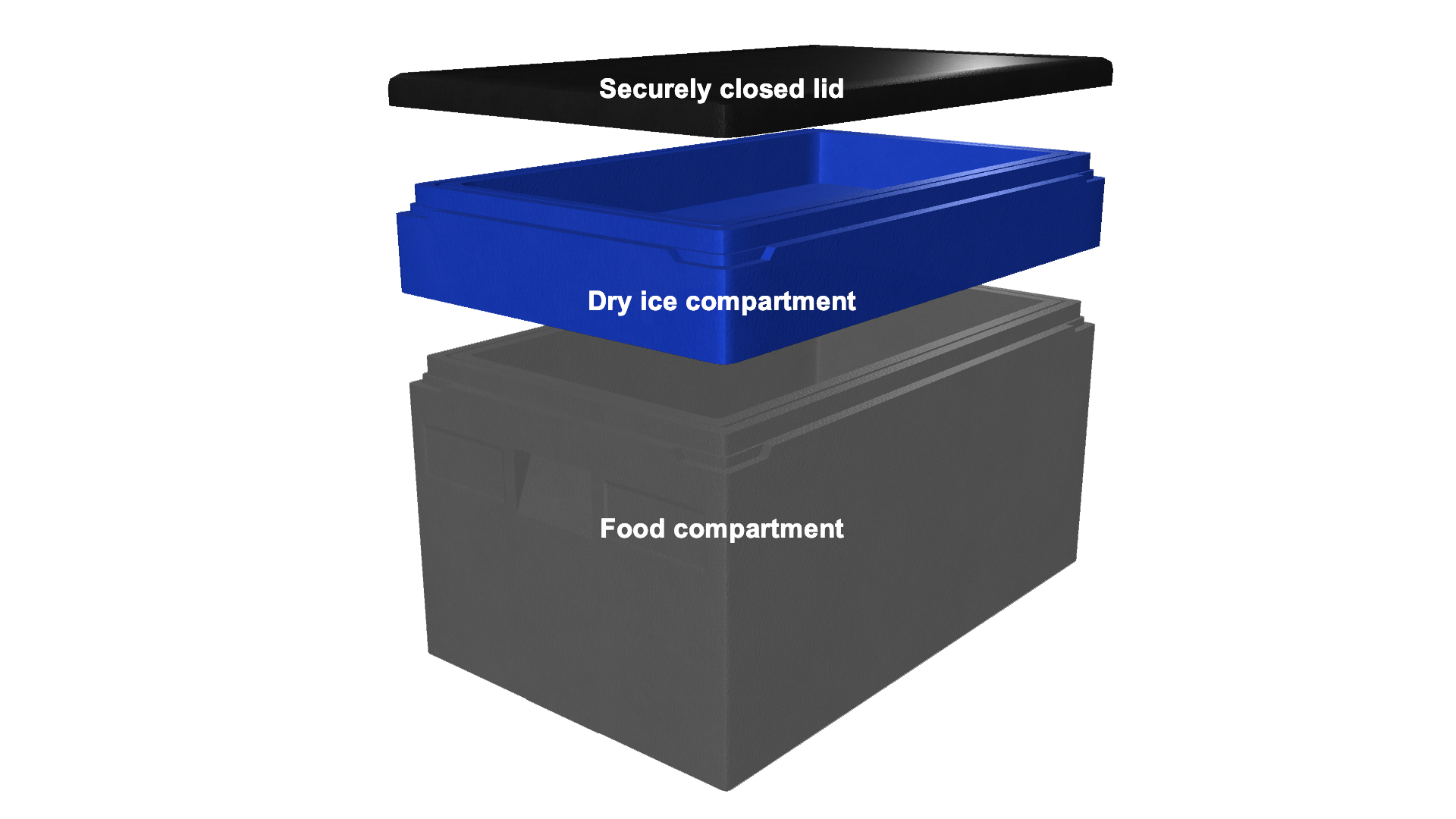

Simplified diagram of the MiniCryo box

Small transport boxes filled with dry ice snow

The combination of SnowDrop (Messer) and MiniCryo (Olivo) is ideal for ensuring that individual deliveries reach the end customer well cooled. The SnowDrop station produces dry ice snow from liquid CO₂. It automatically conveys the cooling medium – with a temperature of minus 78 degrees Celsius – into a specially designed compartment in the lid of the MiniCryo transport box supplied by Olivo, a leading manufacturer of refrigerated containers. This charge ensures that the cold chain temperature is maintained for up to 16 hours. The equipment can be used for both chilled and frozen products. The box is optimally insulated and very lightweight, making it perfectly suitable for manual handling.

The Cryo2Pack system for all kinds of portable cooling boxes also facilitates the creation of your own cooling elements within a matter of seconds. This involves special plastic bags being filled with dry ice snow.

Insulated containers and trucks

Next up in size is the Siber system, which Messer also developed in cooperation with Olivo. It comprises insulated containers on wheels and a filling station. Again, the low temperatures are generated by a dry ice filling. The high-pressure liquid carbon dioxide is pumped directly into the refrigerated container’s reservoir, where it expands and partly turns into dry ice. The containers can be used to transport chilled as well as frozen products. The cooling effect is designed to last at least 24 hours.

Cooling with a gas also has enormous advantages when it comes to the large load compartments of trucks. In this case, the noisy cooling unit is replaced by liquid nitrogen. Messer’s EcoLIN system supplies the cooling gas from a nitrogen tank to the truck’s load compartment via a special heat exchanger. Temperature fluctuations caused by the doors being opened are evened out with minimal delay. In comparison to conventional refrigerated trucks, CO₂ emissions can be significantly reduced. A similar system for the refrigeration of small trucks and vans with dry ice snow is currently being developed at Messer. For both systems, Messer is cooperating with its partner Frappa.