NEWS

© 2015-2020 CERN

Liquid nitrogen cools helium for particle accelerator

By Fabrice Mattalia and Régis Woicki, Messer France

France | Liquid nitrogen from Messer is used to bring the world’s largest particle accelerator back to its extremely cold operating temperature after modernization and maintenance work. The ring-shaped Large Hadron Collider (LHC) of the European Organization for Nuclear Research CERN has a circumference of 27 kilometers. The structure is located about a hundred meters underground beneath the French-Swiss border near Geneva. The LHC is divided into eight sectors. Each sector is equipped with extremely strong superconducting magnets that operate at a temperature of -271°C – which is colder than deep space. The magnets are cooled with helium, in order to maintain the constant temperature required for superconductivity. When the accelerator has to be cooled down again once work has been completed, the helium is first pre-cooled with liquid nitrogen. The noble gas is then further cooled in two subsequent process steps until the magnets achieve the target temperature. CERN researches the composition of matter and the processes that determined the creation of the universe.

Cement cooling for rail and switch sleepers

By Thomas Weichmann, Messer Industriegase

Germany | Messer supplies liquid nitrogen to RAIL.ONE, a leading manufacturer of rail and switch sleepers made of concrete. The gas is used to cool the cement at the Schwandorf site. The ultramodern plant produces up to 180,000 running meters per year of prestressed concrete switch sleepers. The temperature of the cement directly affects the quality of the concrete and thus the quality and safety of the product. RAIL.ONE has been producing concrete sleepers for Deutsche Bahn since 1954. As part of the international PCM RAIL.ONE Group, the company markets concrete sleepers and rail track systems for metropolitan and intercity rail links and also provides engineering services and turnkey plant construction solutions.

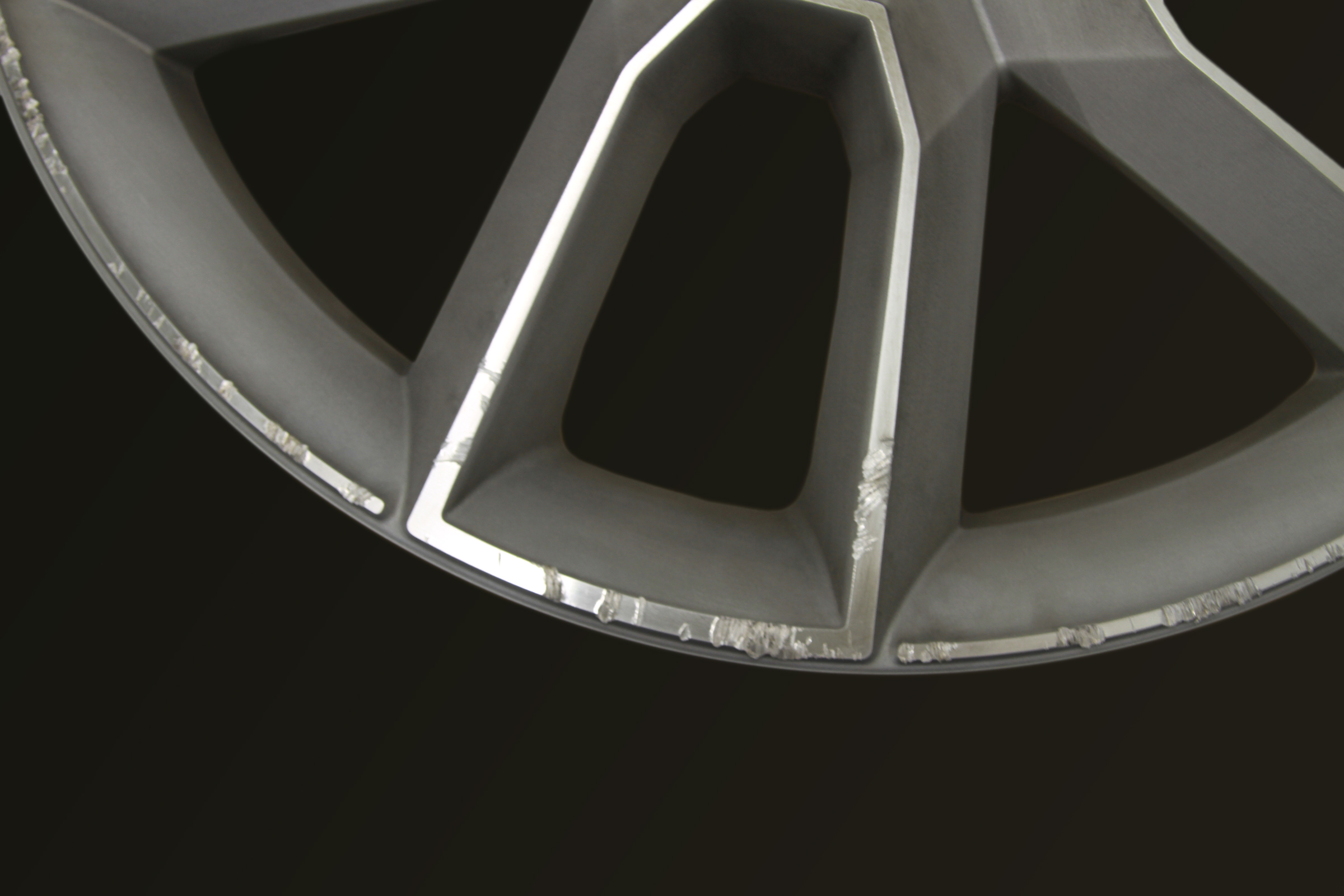

Repairing aluminum wheel rims with Aluline

By Reiner Knittel, Messer Schweiz

Switzerland | Swiss Reparaturzentrum 24 in Birmensdorf specializes in the repair of high-quality aluminum wheel rims. Because aluminum is a relatively soft metal, aluminum rims are susceptible to severe mechanical impacts, such as accidental curb contact. Technician Herbert Schön worked on specific laser performance improvements and, in collaboration with Messer, developed an optimized process: After the rim has been thoroughly cleaned, laser metal deposition is used to eliminate the damage. The process uses Messer’s Aluline He15 N as a shielding gas. The aluminum alloy must not be overheated during this welding procedure. Following metal deposition, the rim is CNC machined and restored to its original dimensions. In the final step, the rim gets a clear coat powder coating. “After that,” Herbert Schön insists, “the rim is just like new again.” The average cost of the repair, however, is about 50 to 70 percent less than the price of a new wheel rim.