News

gas aktuell No. 27, 1984

Continuous operation

6,000 sausages per hour

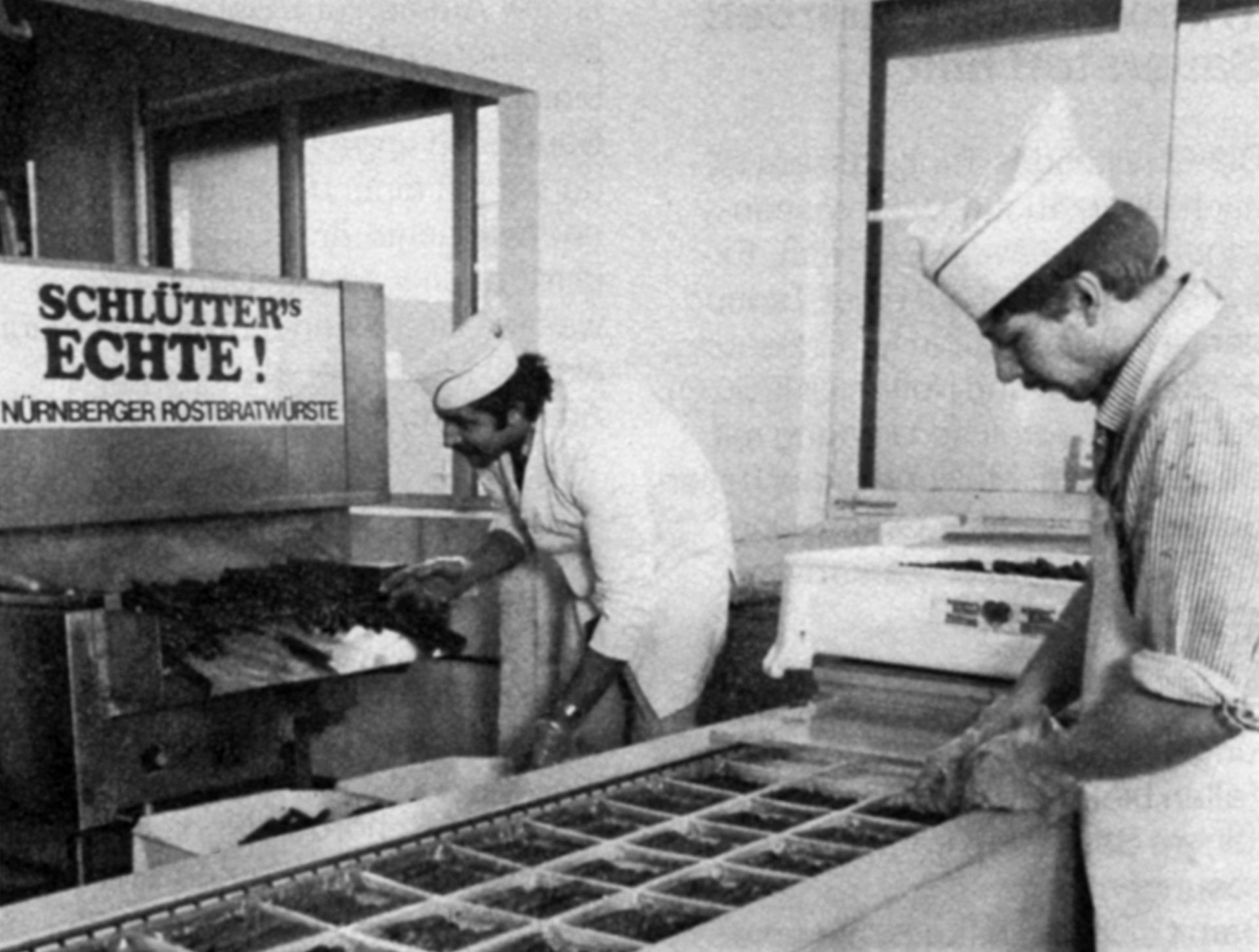

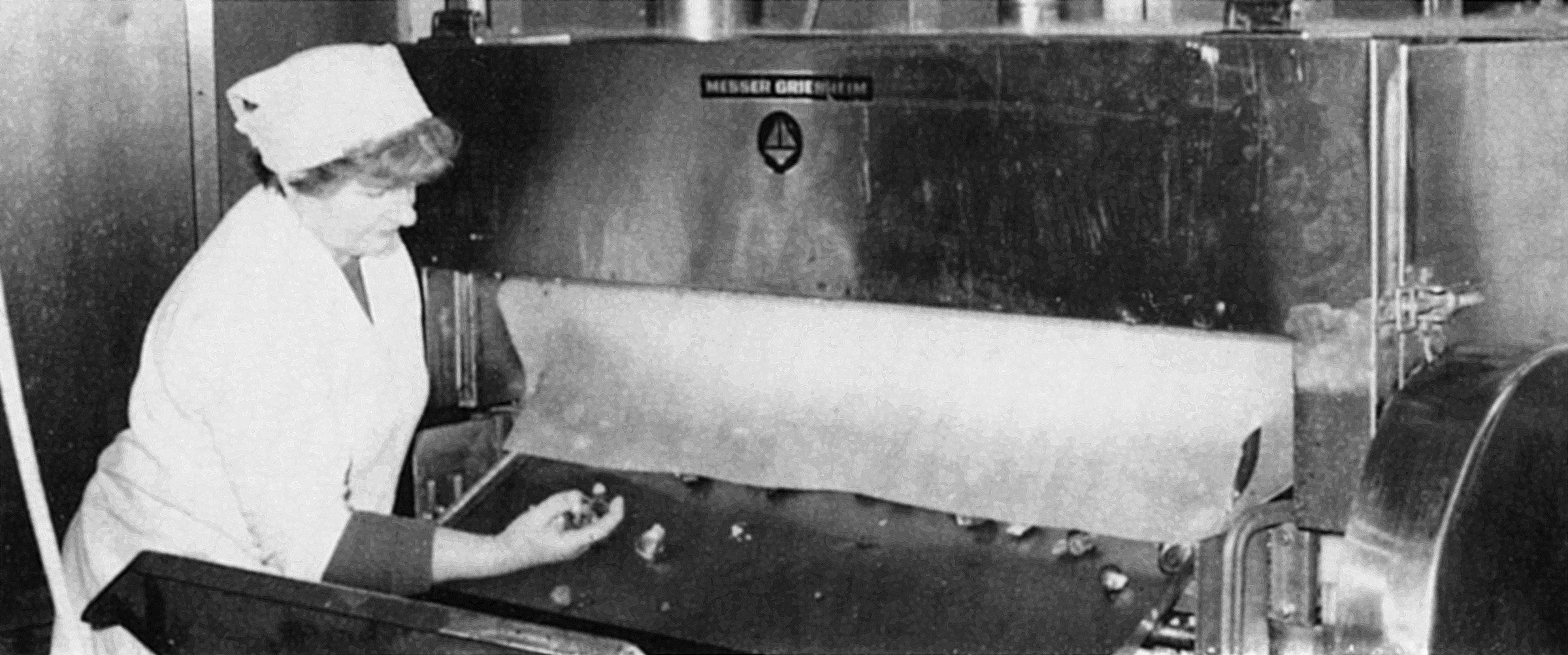

The grilled sausages are cooled in the tunnel freezer and then sealed in airtight packaging.

The first grilled sausage assembly line is operating in Nuremburg, Germany. Master butcher Gerhard Schlütter, the inventor of the conveyor belt grill, is pleased with the growing demand: “The scheduled sausage and delivery volume is now 40,000 units per day. The next expansion phase will enable us to produce up to 12,000 sausages per hour.” Mass production on this scale requires a sausage cooker and the indispensable grill, of course, but it would also not be possible without an equally essential means of production: the Cryogen® Rapid Tunnel Freezer. Under cold nitrogen gas, it cools the grilled sausages down from 95 ºC to less than 8 ºC in six minutes. That means “Schlütter’s Originals” can move right on to the next section of the assembly line, where they are packaged in plastic film. There, too, Messer Griesheim and its subsidiary Buse Gase help ensure consistent quality. A protective gas mixture of nitrogen and carbon dioxide under which the sausages are packaged protects them against harmful atmospheric oxygen and, together with the rapid cooling, helps give the sausages a four-month shelf life. As a result, the consumer receives their “Nürnberger” sausages – a hearty, heartfelt tradition – appetizingly packaged in airtight, clear plastic film.

Gase+Kälte No. 18, 1985

Hydrogen in the tank

Does it really reduce emissions dramatically or not so dramatically? Does it release carcinogenic substances or not? Does it also mean there has to be a speed limit? It’s easy to guess what it’s all about: studies about the pros and cons of catalytic converters now fill rows of filing cabinets – but they apparently fail to reveal any obvious-yet-brilliant answers.

A far more elegant solution would be a fuel that burns cleanly and doesn’t even need exhaust gas purification in the first place. Well, it turns out that such a fuel exists, and experts have already known about it for more than 2,000 years now – hydrogen. Produced from water, it burns back into pure water.

But hydrogen, too, has strings attached: the main one is its extremely low energy density. It takes a 60-kg steel cylinder to transport 90 grams of hydrogen. The weight ratio of contents to packaging improves significantly, however, if you liquefy the hydrogen at a temperature of -253 °C.

Hydrogen fuel certainly won’t resolve our current pollution worries. And it will not be able to replace gasoline anytime soon. That’s not just because a family with children wants all that trunk space when it goes on vacation: with existing production methods, liquid hydrogen is also still too expensive to use as a fuel. From a long-term perspective, hydrogen probably has a bright future – especially when the fossil fuel supplies of oil and coal start to dwindle and when scientists find less expensive ways to produce hydrogen.

This test vehicle, a BMW 735i, travels more than 400 km on a super insulated 130-liter tank of liquid hydrogen fuel.

gas aktuell No. 44, 1993

Turning old products into new ones

Cryogenic separation and grinding of composites enables “true” recycling

With nitrogen cooling, composites can be easily separated and then fine ground.

The first prerequisite for “true” recycling, i.e. converting waste back into the original product, is a clean separation of the components of composites. For the individual components to be suitable for the production process, often they must then be ground to a sufficiently fine powder. That’s why the so-called Cryogen® Recycling from Messer Griesheim comprises two sub-steps: the cold of the liquid nitrogen embrittles most composite materials, especially plastics, rubber and many metals. The different thermal expansion coefficients of the individual components create shear forces that break the bonds enough for the components to separate on their own or with minimal mechanical effort. The next step is the grinding and sifting of the shredded, coarse materials. By cooling with liquid nitrogen, even hard-to-grind materials can be ground into such fine powders so that, in many cases, the original product can be manufactured again. In Krefeld, Germany, Messer Griesheim operates a pilot plant to demonstrate cryo-recycling processes in which the process parameters are optimized for the various application cases. But Cryogen® Recycling is also mobile: nitrogen supply and metering along with the instrumentation and control technology are all transportable, which means they can be installed on-site and ready for testing in short order.

Gase+Kälte No. 19, 1985

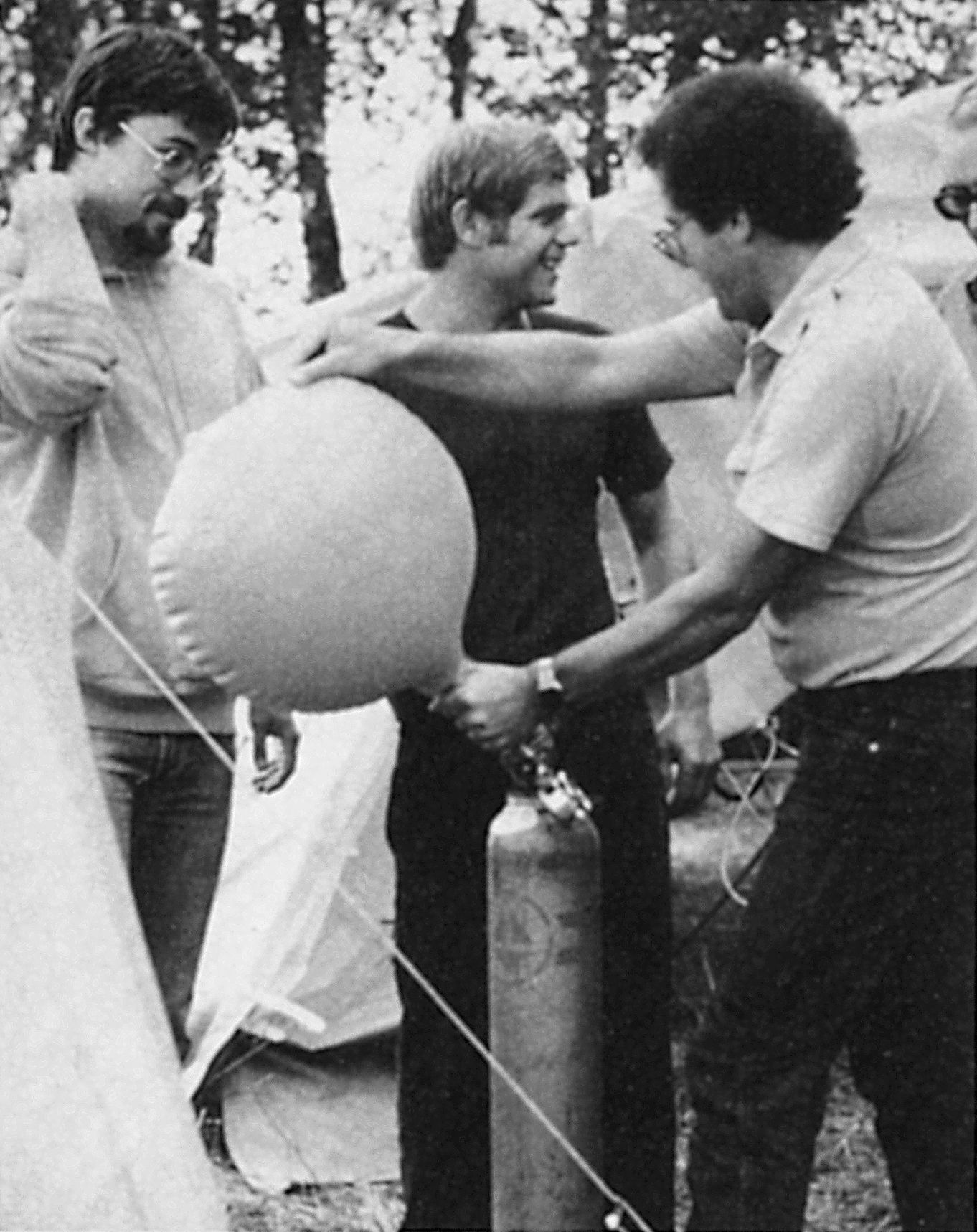

Balloon lifts radio antenna to 80 m

Once a year, the German Amateur Radio Club (DARC) sponsors a radio competition. The winner is the person who establishes the most radio connections. And that takes a good antenna. However, amateur radio enthusiasts are not easily satisfied with “normal” solutions. Instead, they like to experiment. This time they bought themselves a balloon to improve reception by raising the antenna as high as possible. The local chapter in Rüsselsheim was thrilled to learn that Messer Griesheim would donate a cylinder of balloon gas. A balloon filled with its contents was raised 80 m into the air on a thin wire, which served both as retention line and antenna. Messages broadcast from this antenna were heard with good reception quality throughout Germany. Meanwhile, “Junior Radio Operators” speculated about the remaining gas in the cylinder. The balloon never ceases to make children smile. All in all, a successful endeavor for young and old.

Gase+Kälte No. 18, 1985

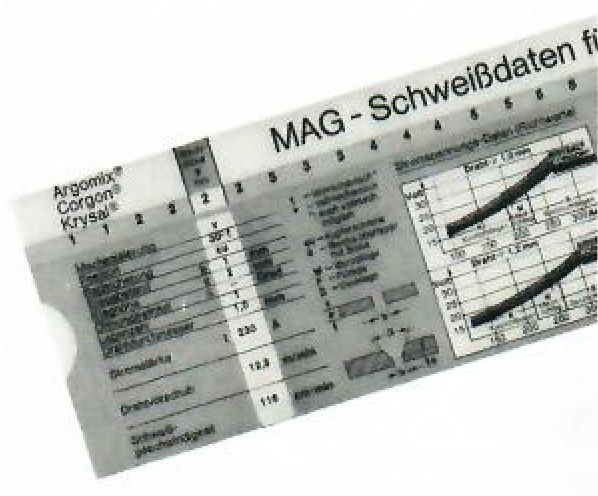

MAG welding data at your fingertips

There is a new MAG data slide rule for fillet welds and square butt joints.

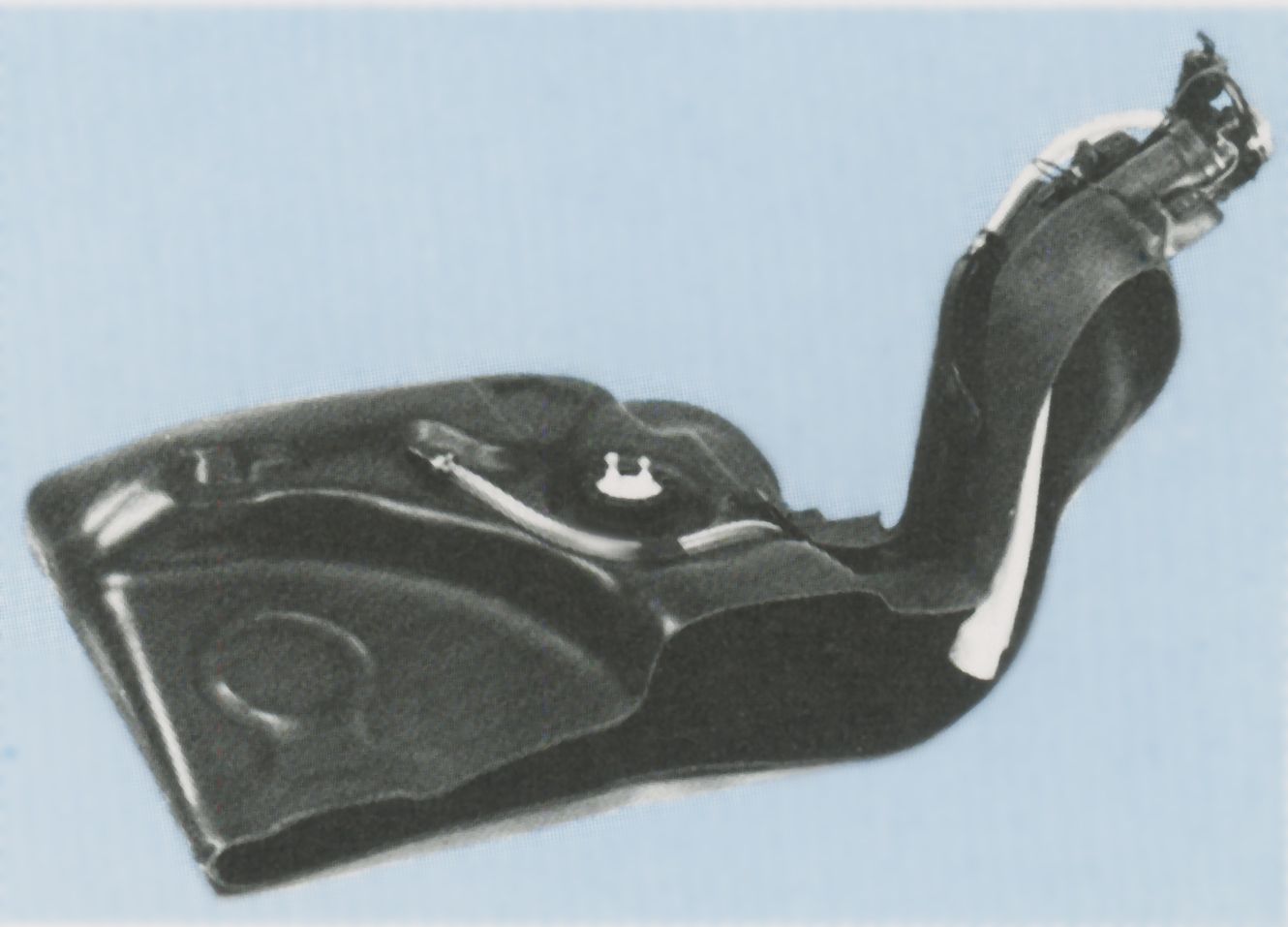

Intricately shaped fuel tanks, such as this one used in the VW Golf, place particularly high demands on the blocking effect of the fluorinated boundary layer

gas aktuell No. 35, 1988

Sealing with fluorine mixtures

Due to the many benefits they offer, polyethylene fuel tanks are becoming more and more common in automotive production. However, the plastic tank has also a drawback, unfortunately: gasoline vapors can penetrate the walls. Increasingly restrictive regulations limit the allowable permeation of vapors through tank walls. Fluorine-nitrogen mixtures temper the interior of the tank, rendering it impermeable. The process has successfully passed the pilot phase testing at a major automaker.

gas aktuell No. 37, 1989

Cryotechnology services in demand

Cryogenic lances were used to inject liquid nitrogen into the ground at the municipal railway construction site in Gelsenkirchen, Germany, to stabilize the soil during underground repair work.

The importance of customer service in gas applications has grown dramatically in recent years. Along with the supply of industrial gases, there has also been more and more demand for expert advice and service. The service teams rely on proven processes and have many years of experience. Now the quality of the pipe freezing process is also recognized in Finnish power plants. A service team fulfilled a contract for the freezing of a cooling water circuit at several points. The targeted freezing of the pipe contents by means of liquid nitrogen forms an ice plug that temporarily serves as a shutoff valve. This allows technicians to replace fittings without having to drain the cooling water system. In the construction of underground shafts and tunnels, the freezing of soil has already been common practice for decades now. It stabilizes the ground and prevents water penetration. A service team demonstrated the benefits of soil freezing at a municipal railway construction site in Gelsenkirchen, Germany. A shield tunneling machine there was immobilized due to a malfunction. The tunnel shield needed repairs in order to get the machine moving again. Before those repairs could be made, the surrounding soil had to be frozen, sealed and stabilized with liquid nitrogen. The chemical industry uses tanks lined with a protective rubber coating to store aggressive media. Those linings must be replaced at specified intervals. The increasing demand for environmentally friendly rubber removal by means of liquid nitrogen has resulted in the largest order to date. Together with Hoechst’s rubberizing shop, Messer Griesheim performed the work on a 500-cubic-meter storage tank. Liquid nitrogen was used to cool the rubber lining down until it became embrittled and could be removed with minimal mechanical effort.

Gase+Kälte No. 19, 1985

Harvest time – freezing time

Liquid nitrogen covers peak load

It all starts with the farmer: The bean harvest is a good example.

When summer harvest time arrives and vegetable varieties ripen in quick succession, the conventional refrigeration systems used by frozen food processors are often overwhelmed. Messer Griesheim then provides temporary assistance with Cryogen® Rapid systems, so companies like TIKO in Wiesloch, Germany, can handle the huge mountains of fresh vegetables. For harvest time operations, a tunnel freezer and a nitrogen tank were set up on short notice. The high cooling capacity of liquid nitrogen (-196 °C) and the time-saving continuous operation of the tunnel make it possible to freeze large quantities of vegetables in a small space very quickly. This enabled TIKO to freeze kohlrabi, cauliflower, Brussel sprouts and beans, as well as other processors to freeze peas and carrots. Shredded white cabbage is also cooled and then processed into sauerkraut. Many food processors rely on Cryogen® Rapid systems for all their freezing needs, and freeze not only vegetables, but also meat, sausage, poultry, game, baked goods and fruits. With stationary, tunnel and spiral freezers – and now immersion freezers – a full range of technically sophisticated equipment is available for many applications. Systems like the ones offered here are particularly attractive to operations whose own refrigeration equipment cannot cope with harvest time. For planning purposes, however, we recommend contacting us as early as possible.

Fast relief with the Cryogen® Rapid Tunnel Freezer.

Separating the wheat from the chaff: Only the highest quality Brussel sprouts are frozen.

Lost and found

There are people who would rather stand in First Class than sit in Third Class. Such people are unpleasant. Kurt Tucholsky

Visit us in the Viennese coffee house

Tradition and progress are on display – as always – at the Messer-Griesheim exhibition stand of the Anuga trade fair in Cologne, Germany. For a little nostalgia, there’s the Viennese coffee house, where folks can converse quite freely. There’s also plenty of tradition in our proven refrigeration and freezing systems. But we never let our love of tradition stand in the way of progress. We have a brand new, super fast immersion freezer for cooling down and freezing hot extrusion products, for example. Just stop by the coffee house and take a look around: you’ll find several more innovations there. We look forward to your visit.

Trade fair dates

Anuga, Cologne

October 12 - 17, 1985 Hall 10, Stand H 6/J 7

Gase+Kälte No. 16, 1984:

The show must go on:

The singing duo Alice and Stephan Waggershausen performing on television against a backdrop with nitrogen fog

Whether at the disco, on stage in the theater, or in the TV studio – entertainers can no longer coax spectators away from the stove without billowing clouds of nitrogen fog. That’s why the cryo service from the Frankfurt plant had to provide yet another foggy backdrop. The occasion was the popular television game show “Einer wird gewinnen” (“Somebody will win”) hosted by Hans-Joachim Kulenkampff. All it took was a water boiler and 150 liters of liquid nitrogen to turn up the heat for vocal stars Alice and Stephan Waggershausen. The hot water heats up the nitrogen and evaporates it. The resulting cold fog is heavier than air and falls to the ground – the photo shows it in front of a wall bathed in red light. In the red spotlight, the fog effectively accentuated the performance of the song “Zu nah am Feuer” (“Too Close to the Fire”).