By: Editorial Team

Reading time: 4 Minutes

◤ HYDROGEN

Efficiency for the energy transition

Humanity faces a once-in-a-century task. With gases expertise, clearly defined objectives and efficient overall concepts, Messer is doing its part.

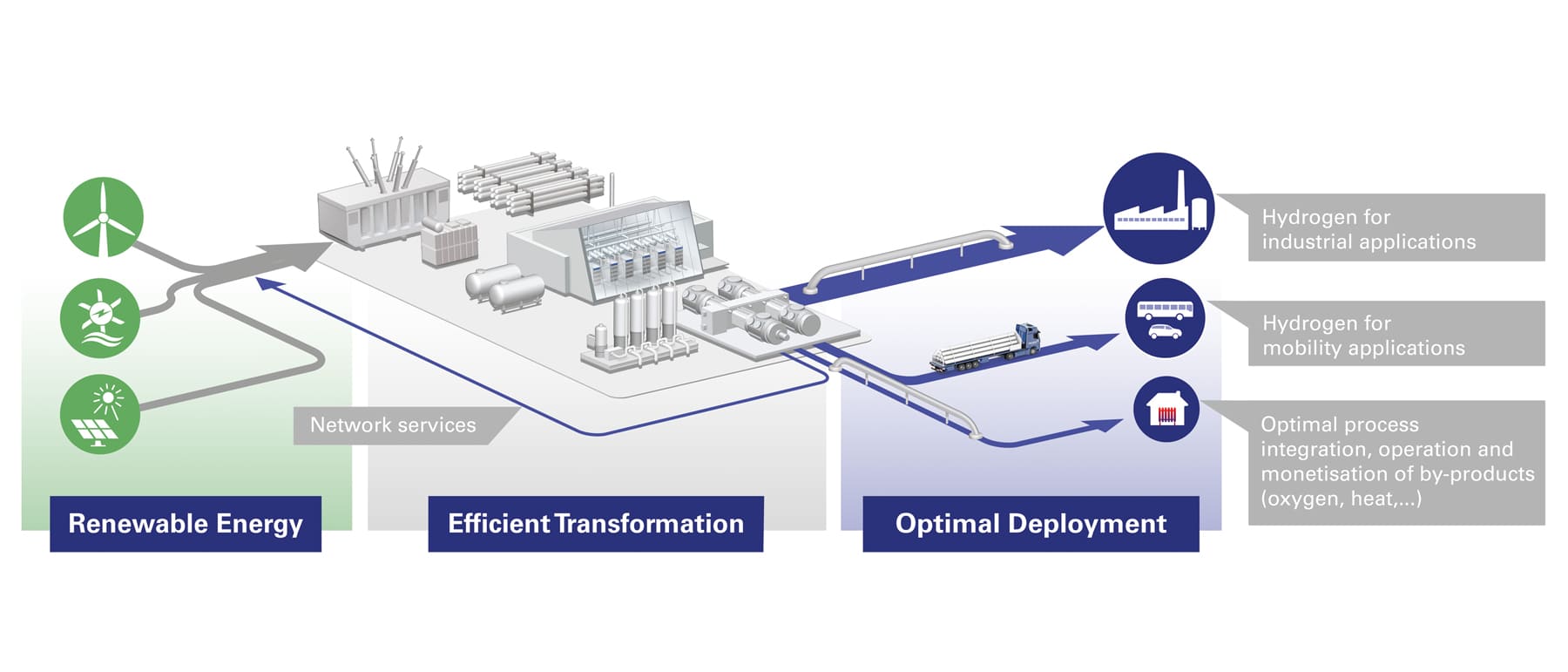

The energy transition needs lots and lots of technology. Expanding the production of electricity from renewable sources, e-mobility, new high-temperature hydrogen-based processes, expanding the electrical grid for the distribution of wind and solar power and new users, new storage options and, not least, a hydrogen economy with large capacities for the production, distribution and utilization of green gas. Entire industries are confronting the technical challenges. This will change the world as we know it – and it is necessary in order to prevent harmful environmental impacts caused by climate change.

But sustainability also has an economic side. What fails to pay long-term dividends won’t last. Sometimes there are unintended consequences: in April 2022, green hydrogen became cheaper than gray hydrogen for the first time. The war in Ukraine and Russia’s export policy had driven the price of natural gas unimaginably high. That also made the gray hydrogen produced from it more expensive. How much longer this crisis-driven boost will persist, no one can say.

❝

Now we know the statutory boundary conditions, such as the precise definition of clean hydrogen and the eligibility of certain systems and technologies.

Andreas Noky, Project Manager for Hydrogen Refueling Stations at Messer

Political course-setting in Europe

Those circumstances bear no resemblance whatsoever to another political situation: the Renewable Energy Directive II (RED II) of the European Union is designed to set a strategic course. Having existed in its current form since 2018, a revision with more ambitious goals is currently being drafted. Although the latest version has yet to be finalized, it already contains the key benchmarks, explains Andreas Noky, project manager for hydrogen refueling stations at Messer: “Now we know the statutory boundary conditions, such as the precise definition of clean hydrogen and the eligibility of certain systems and technologies. This also relates to the accounting of greenhouse gas reduction quotas, which are very important for a profitability calculation. Against that background, we can make realistic estimates and robust proposals.” In collaboration with specialized partner companies, Messer is focusing here on solid solutions in three segments.

❝

We help our customers optimize the technical and economic parameters of the plant operation.

Marco Golbach, Project Manager for On-Site Hydrogen Production at Messer

On-site concept for the production of green hydrogen

The holistic design of the electrolysis plant and its optimized operation are essential to ensure the profitability of green hydrogen production. It is important to incorporate the electrolysis plant into existing production processes as seamlessly as possible, and no less importantly, the electricity must be procured in a cost-efficient way. “Electrolysis units can be operated very flexibly. Unlike steam reforming plants, they achieve their maximum energy efficiency in partial-load operation. For example, you can run them at full load only when green electricity is available in large quantities at low cost. In this way, they also help stabilize the power grids – for which they are remunerated, by the way,” explains Marco Golbach, Messer’s expert in this area. “We help our customers optimize the technical and economic parameters of the plant operation. We also handle the profitable marketing of excess hydrogen along with the byproducts : oxygen and heat energy.”

One-stop shop for bus operators

The energy transition requires a transportation transition: Fleets of buses, for example, will be gradually converted to operate without fossil fuels. The hydrogen-powered fuel cell is the best way to accomplish this. With a one-stop shop, Messer and Toyota Tsusho offer bus operators a convenient solution, perfectly implemented by competent partners. Bus fleet operators receive the hydrogen-powered buses, the financing, the hydrogen supply and infrastructure, and all services required for operation – all from a single source. They are charged per kilometer driven or per CO₂e-emissions reduction.

H₂ refueling solution

Hydrogen vehicles need refueling stations. Messer has already been assuring the supply and refueling for one of the world’s largest fleets of fork lift trucks at a well-known automotive manufacturer in the USA since 2004. For many years now, Messer has also provided the technology and supplied the hydrogen for one of the largest fleets of H₂ buses there. All this expertise is bundled in the “H₂ refueling solution.” On the installation of large and small H₂ refueling stations, Messer collaborates with specialized partners who are among the technology and market leaders in their respective segments.